SS304 SS316 25 mm, 38 mm, 50 mm Metal Pall Ring Ethane Desulfurization Industry

Basic Info.

| Model NO. | 25mm, 38mm, 50mm, 76mm |

| Effect | Improve Mass Transfer Efficiency |

| Source | Stainless Steel |

| Acid Resistance | No |

| Corrosion Resistance | No |

| Thickness | 0.5-1mm |

| Sample | Free |

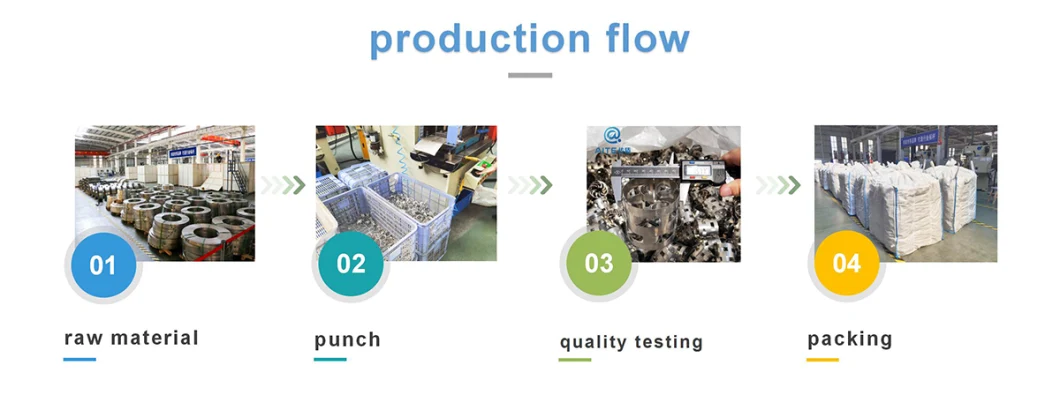

| Craftsmanship | Punch |

| Size | 10mm, 16mm, 25mm, 38mm, 50mm |

| Delivery Time for 5m3 | 3-5 Days |

| Packing | Ton Bag |

| Bulk Density | 193-900 Kg/M3 |

| Certification | ISO 9001:2008 |

| Feature | Heat Resistance |

| Dry Packing Factor M-1 | 66-1300 |

| Surface Area | 60-350 M2/M3 |

| Free Volume | 95% |

| Shape | Cylindrical Hollow out |

| Transport Package | Ton Bag |

| Specification | 16mm, 25mm, 38mm, 50mm, 76mm |

| Trademark | Aite |

| Origin | China |

| HS Code | 8419909000 |

| Production Capacity | 1000 Cubic Meter Per Month |

Product Description

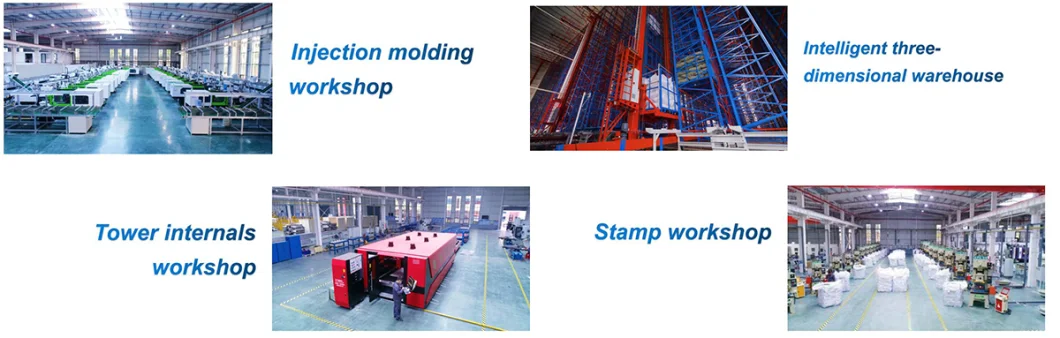

Jiangxi Aite Mass Transfer Technology Co.,Ltd continue to improve our core competiveness. It is committed to the R & D and manufacturing of more than 100 kinds of products such as plastic packing, metal packing, ceramic packing, packing tower mass transfer equipment, tower internals, trays, vessels tower, fire pipes, new fire fighting materials, water treatment materials, etc. and create a bright future with scientific research and development.There are 80 automatic production lines in the main workshop of the base, and the production processes of precision mold ,sheet metal stamping, precision stamping, injection, molding extrusion are standardized and automated, with the annual production capacity of 200000 cubic meters of mass transfer materials and 10000 tons of CPVC new materials.

Product Description

304 316 25 mm, 38 mm, 50 mm Metal Pall Ring Ethane Desulfurization Industry

Metal Pall Ring Tower Packing is one of the most common and well-known bulk packing materials. It is made of sheet metal and has a special structure. There are two rows of windows inclined inward on the annular wall. Each row of windows has five lobes that bend inward and point to the center where the tongue contacts each other. The positions of the upper and lower windows are staggered. Generally, the area of the window is about 30% of the whole ring area. The window on the ring wall makes the distribution and mass transfer efficiency of liquid and gas in the package better than that of Raschig ring. Main features: small flow resistance, uniform liquid distribution, high mass transfer efficiency and large gas flux Application scope: it can provide gas-liquid distribution transmission efficiency. It is suitable for carbon dioxide degassing tower, ozone contact reaction tower, etc. as contact packing and other reaction towers

| Sizemm | Specific Surface Aream2/m3 | Void Ratio% | Stacked NumberPCS/m3 | Stacked WeightKG/m3 |

| 16×16×0.3 | 362 | 94.9 | 214000 | 408 |

| 25×25×0.4 | 219 | 95 | 51940 | 403 |

| 38×38×0.6 | 146 | 95.9 | 15180 | 326 |

| 50×50×0.8 | 109 | 96 | 6500 | 322 |

| 76×76×1 | 71 | 96.1 | 1830 | 262 |

Detailed Photos

Packaging & Shipping

Workshop